Laptops and phones with OLED displays boast rich colors with high contrast, but at a higher price. Researchers at the University of Minnesota Twin Cities (UMN) say they have found a potential solution to this price barrier with a 3D printer that could eventually lead people to make their own OLED screens at home.

In the study, published Friday in Science Advances, the researchers used a custom-made printer that fits on a desk and “costs about the same as a Tesla Model S,”says Michael McAlpine, a professor at the University of Minnesota in the mechanical engineering department. and senior author of the study, according to a statement accompanying the UMN announcement.

While OLED panels are typically made by large companies like LG Display in large microfactories, research could eventually lead hobbyists to make cheap OLED panels in their own workshops, according to the university.

“The good part of our research is that manufacturing is fully built in, so we’re not talking about a 20-year future with some kind of pie-in-the-sky vision,” McAlpine said. “This is something we’ve actually made in the lab and it’s not hard to imagine that you could translate this into printing all sorts of displays at home or on the go in just a few years on a small portable printer.”

The newly printed flexible OLED display indicates that it can be used not only for smartphones and laptops, but also for widescreen TVs and monitors.

OLED panels have been 3D printed before, but not as well. UMN refers to previously “partially printed”OLED panels that depended on centrifugation or thermal evaporation for use in actual devices. The authors of the new article also used 3D printing to make the previous OLED screen, but had difficulty achieving uniform light-emitting layers.

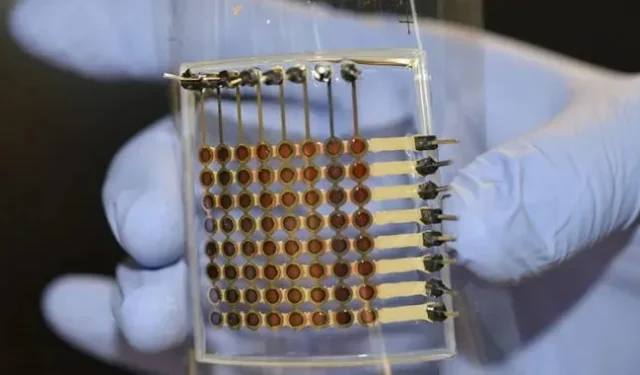

But by changing the process to include two different types of 3D printing — spray printing for active layers and extrusion printing for electrodes, interconnects, insulation, and encapsulation — the researchers were able to create six layers to make a flexible OLED panel roughly 1.5×1 in size.. 5 inches with an 8×8 grid of functioning pixels that could display legible text.

“The device demonstrated relatively stable emission over 2,000 bending cycles, suggesting that fully 3D printed OLEDs could potentially be used for important applications in soft electronics and wearables,” said Ruitao Su, study author.

In addition, the paper states that 3D printed displays could lead to new designs “such as larger form factors, displays intertwined with soft robotics for electroluminescent body parts, and three-dimensional (3D) structured pixel arrays for holography. “.

The researchers will then work on making the 3D-printed OLED panels brighter and higher resolution.

Of course, even the most serious hobbyists will have a hard time finding a 3D printer of the class that the UMN researchers use. However, if the technology becomes more widely available, we could consider a lot of interesting manufacturers’ projects and maybe even the opportunity to repair your own OLED screen the next time you drop your phone or laptop.